Diesel engines power many vehicles and machinery worldwide, renowned for their efficiency and durability. However, their environmental footprint, particularly particulate matter and noxious gas emissions, has been a cause for concern. This is where Diesel Particulate Filters (DPF) and Diesel Oxidation Catalysts (DOC) play a pivotal role. DPFs are engineered to capture soot and ash particles in diesel exhaust, preventing them from being released into the atmosphere. Concurrently, DOCs are designed to initiate a chemical process that converts harmful gases such as carbon monoxide (CO) and hydrocarbons (HC) into less harmful emissions like carbon dioxide (CO2) and water (H2O). Together, these technologies form the cornerstone of modern diesel emission control systems, helping vehicles meet stringent environmental regulations. The importance of DPF and DOC extends beyond compliance; they are key to reducing the environmental impact of diesel engines, making them more acceptable in a world increasingly focused on reducing pollution and protecting air quality.

Understanding Diesel Particulate Filters (DPF)

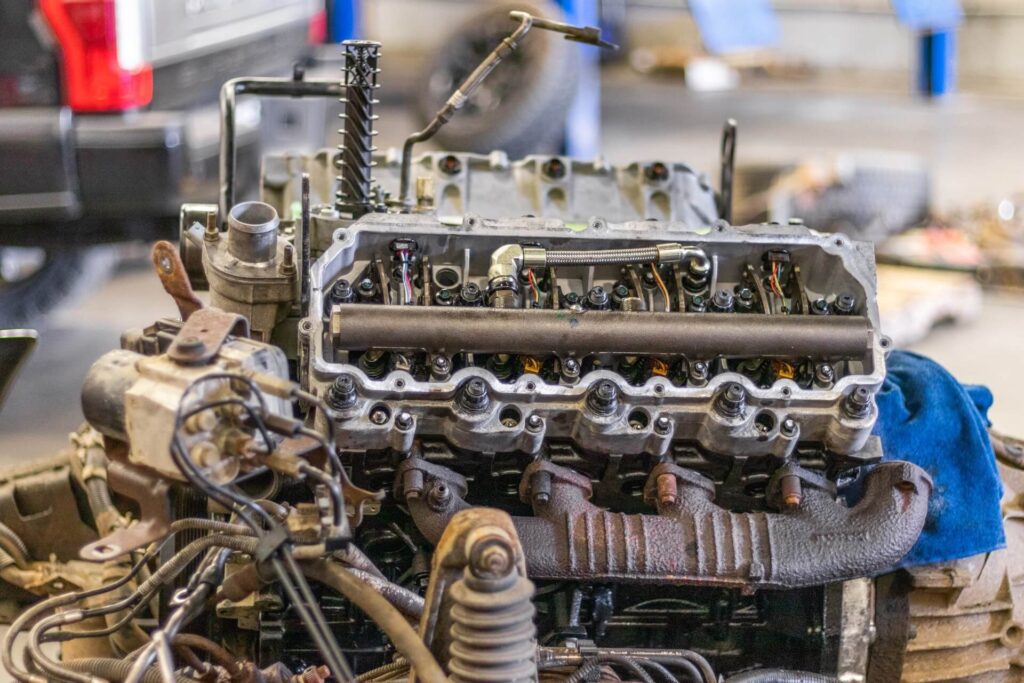

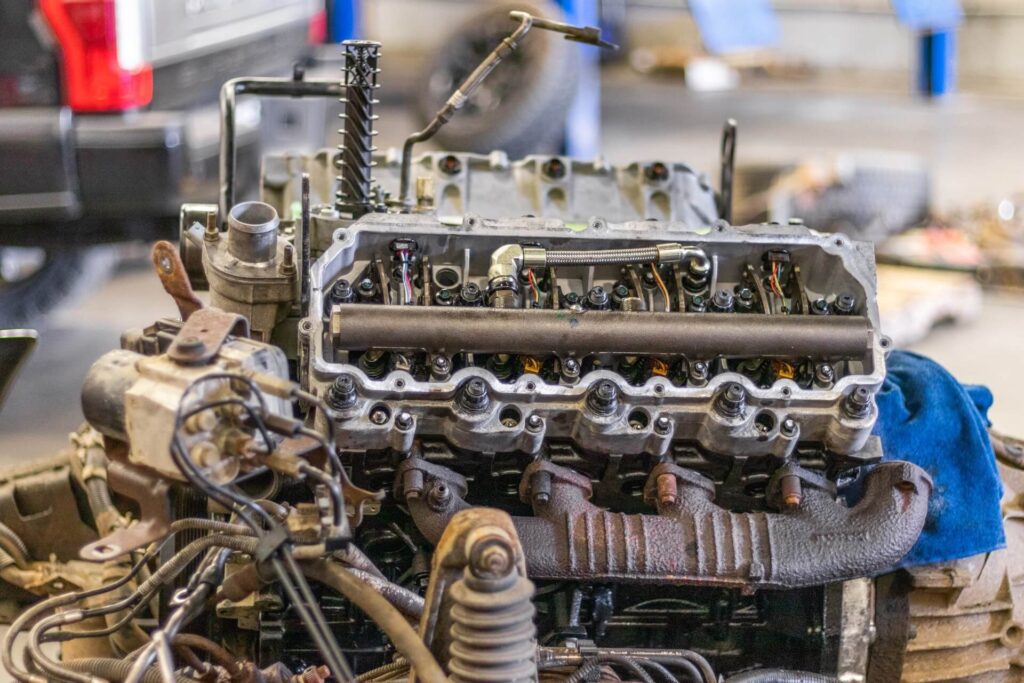

Diesel Particulate Filters, commonly known as DPFs, are essential in reducing the environmental impact of diesel engines. By design, DPFs trap soot and ash particles produced during the combustion process, preventing them from being expelled into the atmosphere. If released, these particles contribute significantly to air pollution and pose health risks. The DPF captures these particles on a filter and, through a process called regeneration, periodically burns them off at high temperatures, turning them into less harmful gases.

Maintenance is a key aspect of ensuring the longevity and effectiveness of a DPF. Regular cleaning is necessary to prevent the filter from clogging with ash— a byproduct of the regeneration process. Cleaning methods vary, including manual filter removal for servicing and automated processes that burn off accumulated soot without removing the filter from the vehicle.

However, DPF systems are not without their challenges. Issues such as excessive soot accumulation, triggered by short journey times where the engine does not reach the optimal temperature for passive regeneration, can lead to reduced efficiency and potential system failure. Additionally, improper maintenance or prolonged use without adequate servicing can exacerbate these issues, leading to costly repairs or replacements.

Understanding the critical role of maintenance in the life cycle of a DPF is paramount. Adequate attention to the system not only prevents mechanical failures but also ensures the vehicle runs more efficiently, contributing to cleaner emissions. Despite these challenges, DPF technology has proven to be a crucial step in mitigating the environmental impact of diesel engines, aligning with global efforts to reduce airborne pollutants and safeguard public health.

The Role of Diesel Oxidation Catalysts (DOC)

A Diesel Oxidation Catalyst, or DOC, is an integral component of a diesel engine’s exhaust system, tasked with reducing the engine’s environmental impact. The DOC works by facilitating a chemical process that transforms harmful gases emitted by the diesel engine into less harmful substances. Specifically, it targets carbon monoxide (CO) and various hydrocarbons (HC) present in the exhaust gas, oxidizing them into carbon dioxide (CO2) and water (H2O), which are significantly less detrimental to environmental and human health.

The operation of a DOC is a fascinating demonstration of chemical processes at work. The catalyst, typically composed of platinum and palladium, accelerates the oxidation of CO and HC without undergoing any change. This reaction occurs when the exhaust gas, warmed by the engine’s operation, passes through the DOC unit, transforming these gases into benign byproducts.

Moreover, the DOC plays a vital role with the Diesel Particulate Filter (DPF) in curbing diesel emissions. It effectively reduces the load on the DPF by converting a fraction of the particulate matter into CO2 and water before it reaches the DPF, thus enhancing the efficiency and longevity of the DPF system. This symbiotic relationship underscores the importance of both components in the overall emission reduction strategy.

Several factors can influence the performance of DOC units, including the quality of diesel fuel used and operating temperatures. High-quality, low-sulfur diesel fuels are preferable as they contain fewer impurities that can potentially deactivate the catalyst. Maintaining the DOC at the optimal operating temperature is crucial for maximizing its efficiency in converting harmful gases.

In essence, DOC units play a crucial role in modern diesel exhaust systems, highlighting the automotive industry’s ongoing efforts to reduce the environmental impact of diesel engines through advanced emissions control technologies.

Modern Developments and Technologies in DPF and DOC Systems

The relentless pursuit of innovation in the automotive industry has led to significant advancements in Diesel Particulate Filters (DPF) and Diesel Oxidation Catalysts (DOC) systems. These improvements are pivotal in enhancing the efficiency and reliability of emission control technologies while extending the longevity of diesel engines.

One of the key advancements is material science, which has dramatically improved both DPF and DOC systems. New materials with higher thermal and chemical durability have been developed, allowing these systems to withstand the harsh conditions within diesel exhausts for longer. This development means that filters and catalysts are less prone to degradation, ensuring they maintain their effectiveness over larger regeneration cycles.

Moreover, regeneration technology has seen noteworthy innovations. Regeneration is clearing the DPF of accumulated particulate matter, essentially ‘cleaning’ it so that it can continue to trap more particles. Advanced control strategies and better thermal management have led to more efficient regeneration, significantly reducing the likelihood of DPF clogging and subsequent engine backpressure issues. Some systems now incorporate active regeneration methods, which can independently initiate the regeneration process without relying on specific driving conditions, enhancing the DPF’s reliability and performance.

Additionally, engine tuning and aftermarket solutions have become increasingly significant. These technologies can optimize engine performance to minimize particulate production at the source, reducing the burden on DPF and DOC systems. Furthermore, aftermarket solutions provide options for upgrades and enhancements to existing emission control systems, ensuring they meet or exceed regulatory requirements.

The ongoing development in DPF and DOC technologies showcases a strong commitment within the automotive industry to environmental responsibility. These advancements contribute to cleaner emissions and signify continuous efforts to innovate and adapt in response to evolving environmental standards and challenges.

The Future of Diesel Emissions Control

In summary, Diesel Particulate Filters (DPF) and Diesel Oxidation Catalysts (DOC) play indispensable roles in minimizing diesel engines’ environmental impact. Through advanced chemical processes and filtration, these technologies significantly reduce the pollutants emitted into the atmosphere, contributing to cleaner air and a healthier environment. Their effectiveness, however, is deeply intertwined with regular maintenance and a clear understanding of their operational principles.

Modern advancements in material science, regeneration technology, and engine tuning underscore a proactive approach toward environmental stewardship within the automotive sector. This continuous innovation enhances the performance and reliability of DPF and DOC systems and aligns with the global endeavor to mitigate air pollution. As the automotive industry evolves, staying informed about these technologies and their developments is crucial for both manufacturers and diesel engine owners, ensuring a future where diesel vehicles continue to meet stringent emission standards.

For those seeking expert advice, maintenance services, or more information on optimizing diesel engine performance while adhering to environmental regulations, DPF Canada stands at the forefront of DPF and DOC technology solutions. Our commitment to innovation and environmental responsibility ensures that your diesel engine operates at its best, contributing to a greener future.